Description

The concept of treating and protecting wood surfaces by burning originates from Japan, giving rise to the method’s name, yakisugi (also known as shou sugi ban). In Finnish, it can be referred to as puun pintahiillyttäminen or hiiltäminen.

Burning the surface of the wood removes sugars and organic matter from the surface and seals the pores of the wood. This treatment:

Enhances the wood’s weather resistance

Cleans the wood surface

Offers a non-toxic way to protect the wood

Does not weaken the structure from within the wood

Does not produce soot when the wood surface is washed, brushed, or oiled after charring

Surface-charred wood to specific measurements for each project.

In your order, you can choose the wood type, treatment (charring, washing, brushing), staining, and surface finishing:

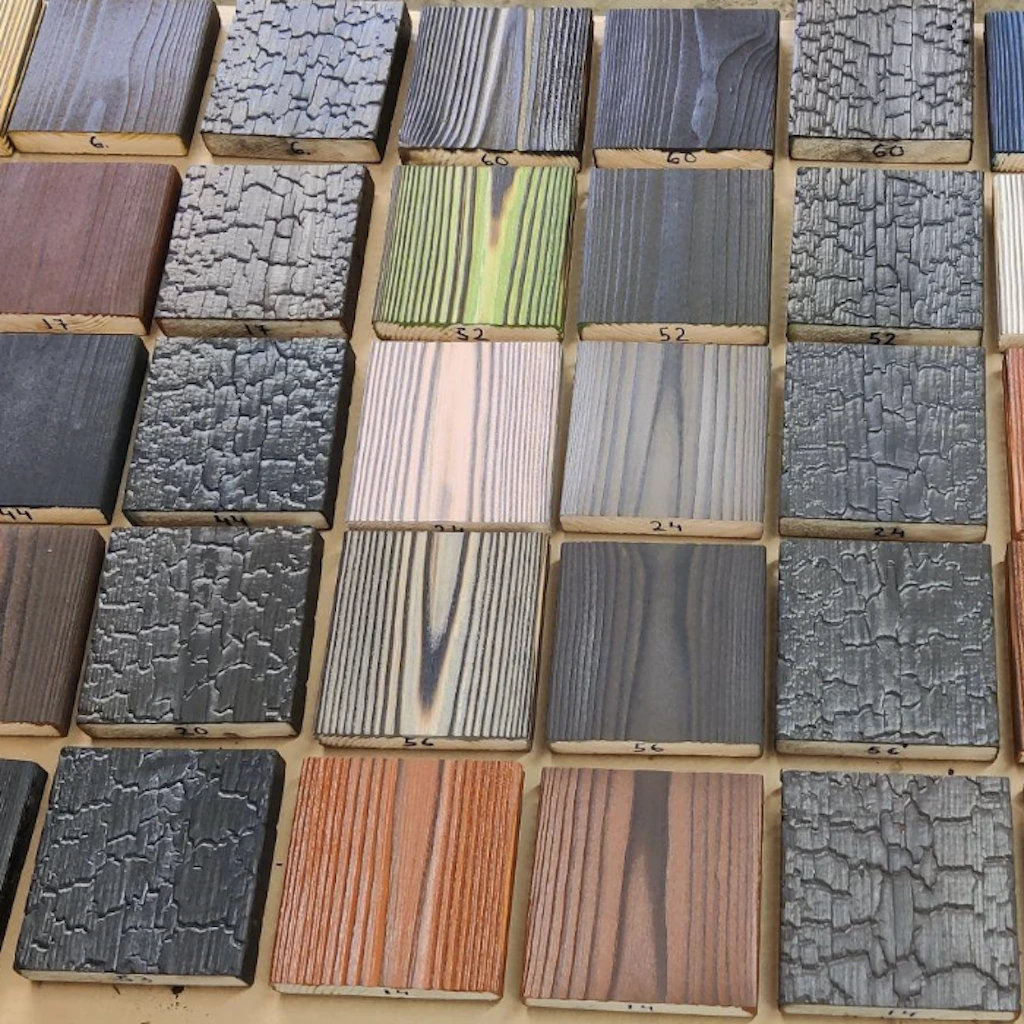

Charred: A product left with a charred surface is the most resistant to weather and moisture stress. The wood surface is burned black by fire, creating a product with a rugged, charred appearance.

Washed: The charred surface is washed with a high-pressure washer, leaving a lively and natural dark brown surface. The surface highlights the difference between spring and summer wood, as well as knots.

Brushed: Brushing after washing softens and evens out the surface, making the product especially suitable for applications like deck planks or sauna benches.

Stained: Charred and brushed or washed surfaces can also be stained to achieve the desired colour shade.

Installing and Working with Charred Wood

Charring only alters the wood’s surface to a depth of 2-4 mm. Apart from the surface, the products are essentially untreated timber. Charred timber can be sawn, drilled, and worked just like uncharred timber.

If products are ordered to specific dimensions, the ends will also receive charring and surface treatment. For other charred wood products, it’s recommended to surface-treat the cut edges with oil (optionally tinted black or brown).

However, when transporting and installing charred surface products, it’s important to be mindful of the surface’s sensitivity to avoid dents and scratches.

For panels wider than 120mm, it’s recommended to use surface fixing with black-headed stainless steel screws. Interior panels and narrower exterior cladding panels can be concealed fixed by nailing at the tongue and groove.

Technical information:

Profiles: UTS, UYS, UTV, UYV

Wood material: Spruce and pine

Surface treatment: Linseed oil

|

Carbon |

||||

|

Thickness |

Width |

€/m |

€/ m2 |

|

|

28 |

95 |

2.86 |

33.60 |

|

|

28 |

120 |

3.83 |

34.80 |

|

|

28 |

145 |

5.10 |

37.79 |

|

|

28 |

170 |

6.53 |

40.8 |

|

|

28 |

195 |

8.12 |

43.92 |

|

|

Washed |

||||

|

Thickness |

Width |

€/m |

€/ m2 |

|

|

28 |

95 |

3.00 |

35.30 |

|

|

28 |

120 |

3.98 |

36.23 |

|

|

28 |

145 |

5.29 |

39.20 |

|

|

28 |

170 |

6.76 |

42.23 |

|

|

28 |

195 |

8.39 |

45.35 |

|

| Brushed | ||||

|

Thickness |

Width |

€/m |

€/ m2 |

|

|

28 |

95 |

3.19 |

37.56 |

|

|

28 |

120 |

4.22 |

38.40 |

|

|

28 |

145 |

5.58 |

41.34 |

|

|

28 |

170 |

7.09 |

44,3 |

|

|

28 |

195 |

8.77 |

47.42 |

|

|

2x Brushed |

||||

|

Thickness |

Width |

€/m |

€/ m2 |

|

|

28 |

95 |

3.43 |

40.38 |

|

|

28 |

120 |

4.56 |

41.46 |

|

|

28 |

145 |

5.88 |

43.56 |

|

|

28 |

170 |

7.44 |

46.50 |

|

|

28 |

195 |

9.13 |

49.37 |

|