Description

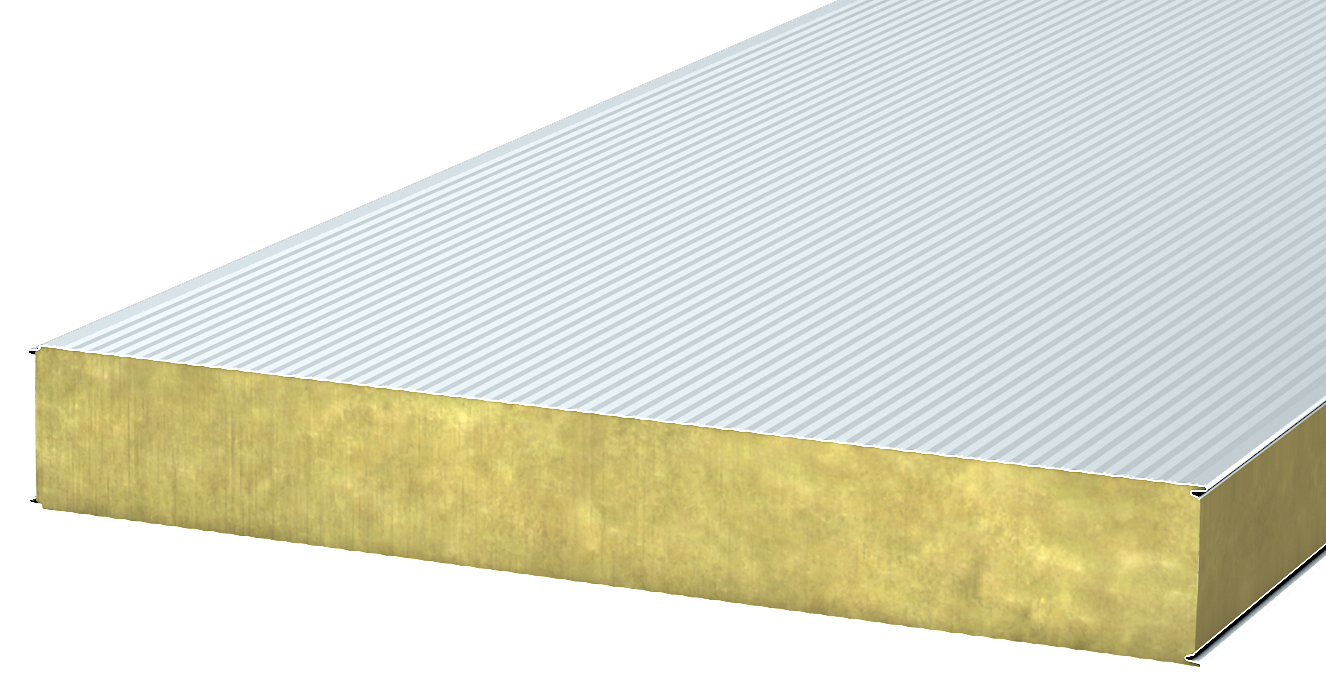

Sandwich panels TENAX are manufactured in a wide range of thickness, with different thermal insulation cores, panel joints, and profiling of the steel facings, all of which have a significant influence on the performance characteristics and the appearance of the structure. Sandwich panels TENAX with mineral wool (MW) core are particularly suitable for the structures with very high fire safety, as well as good thermal performance and sound insulation characteristics. Together with the sandwich panels TENAX the customer can also benefit from the panel design and calculation services, as well as for instructions, detailed drawings, accessories, and materials necessary for panel handling and assembly.

Minimum order 200 m2.

Profiled sandwich panels TENAX TR are particularly designed for multi-span roof structures, with a minimum slope of 5 °.

ADVANTAGES

- Custom made solutions

- Short delivery time (3-4 weeks)

- Engineering and designing support to clients

- Project management support during construction

- Less cutting work and waste at the building site (available panel widths are from 0,6 till 1,2 m)

- Easy to replace the insulation core of panels after project design (for example, from MW to PIR)

- Panel joints are fully compatible with each other (MW, PIR, PUR, and EPS)

- Panels are delivered together with complementary elements (flashings, screws, etc.)

- More than 10 years’ experience in production, execution and delivering of goods