✨ Hello, dear visitor. Buy products at the best factory prices on our website ✨

✨ Hello, dear visitor. Buy products at the best factory prices on our website ✨

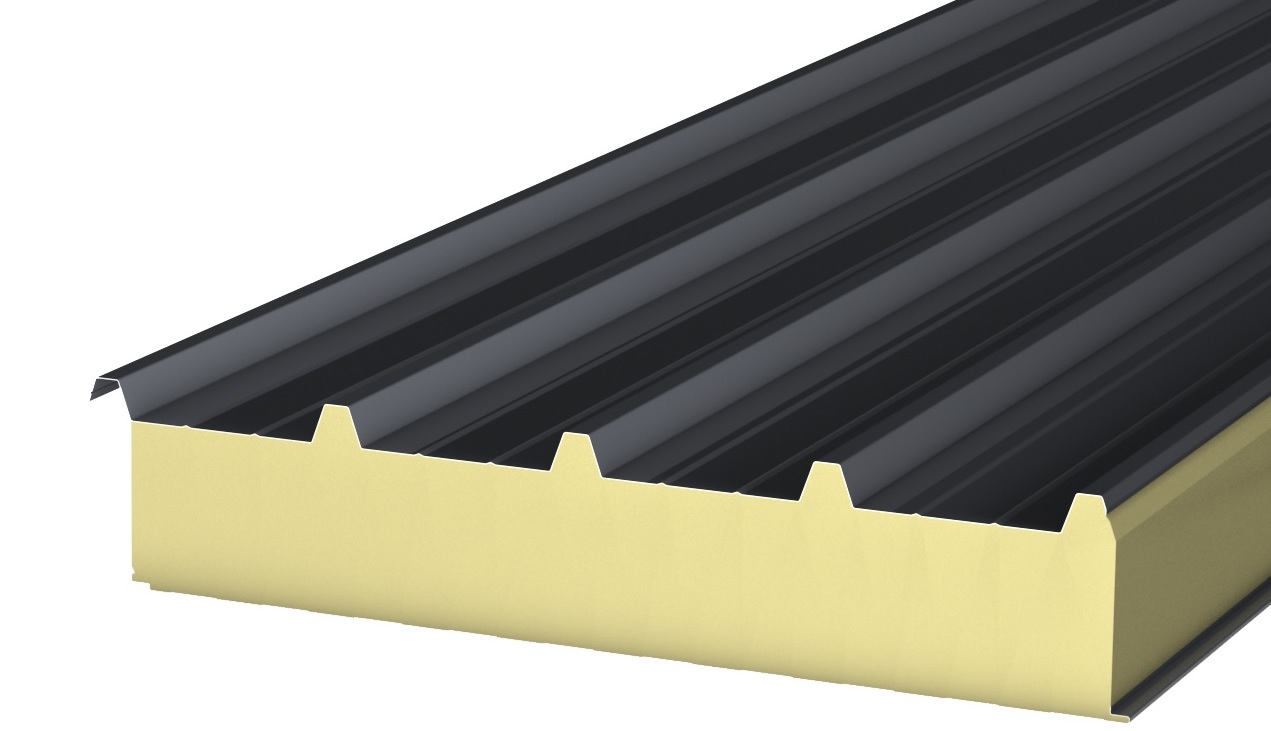

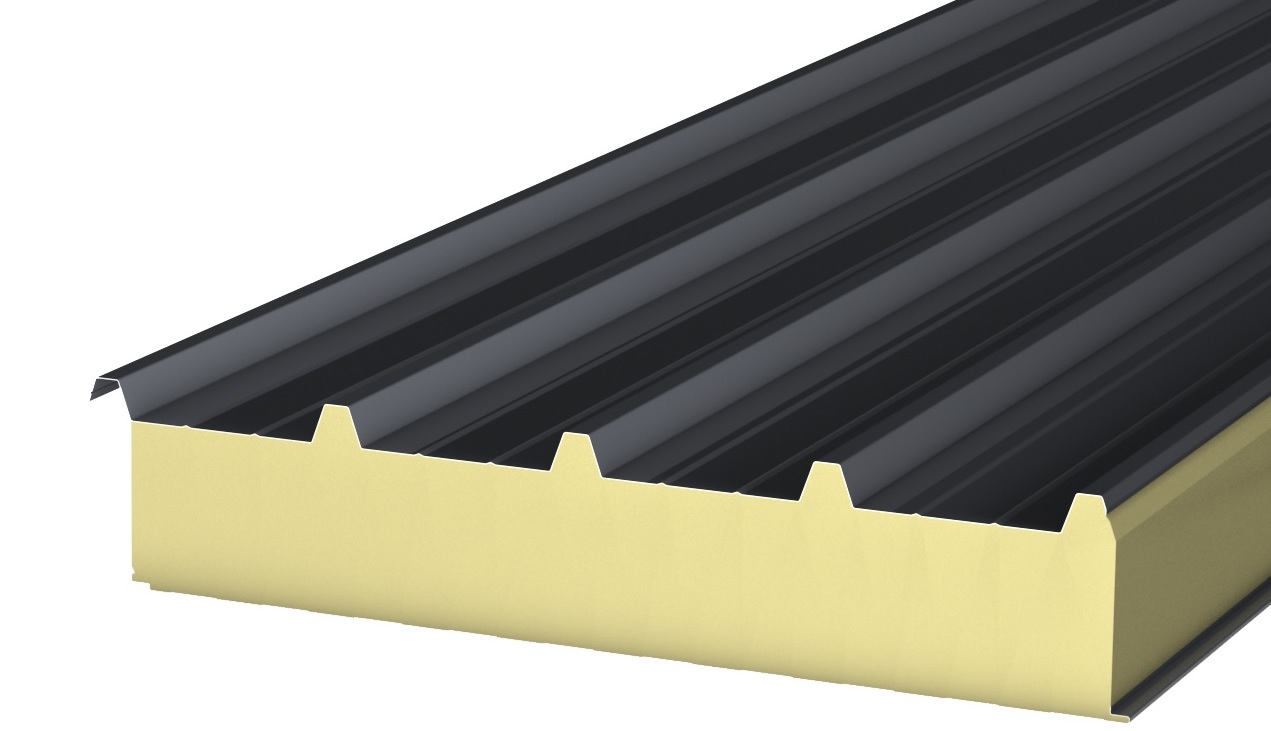

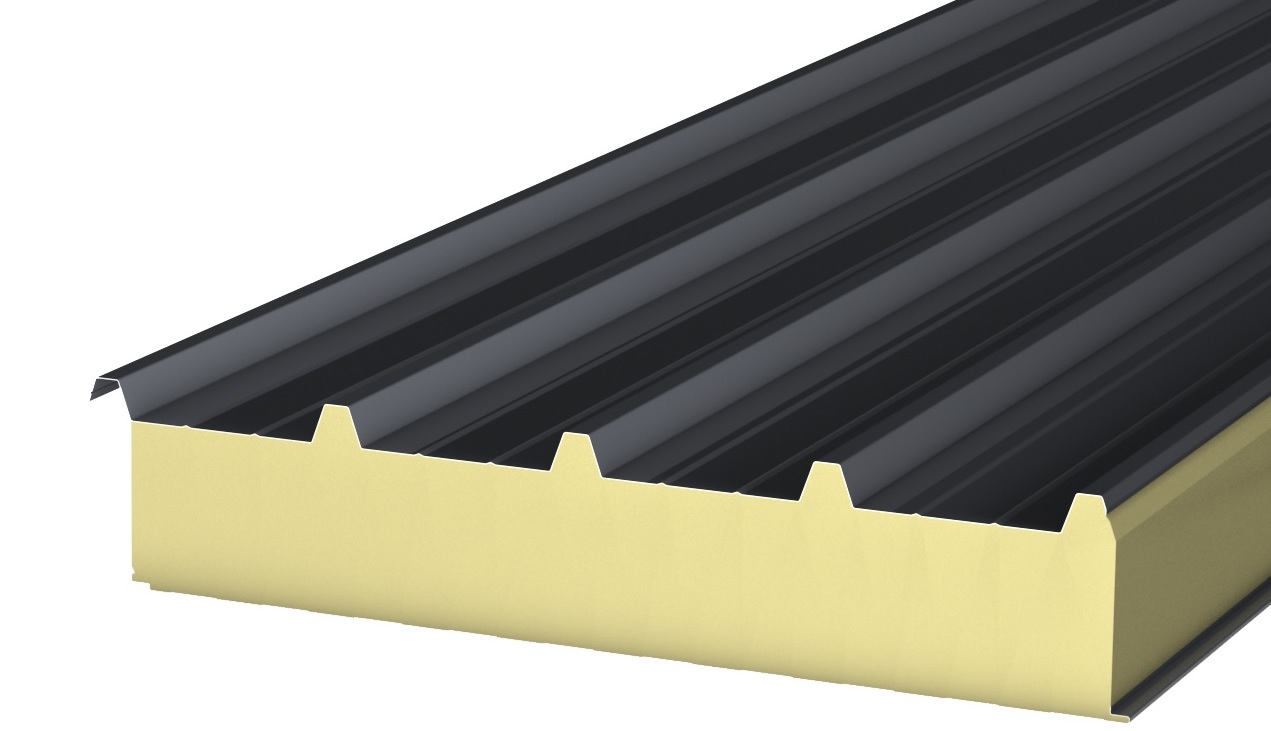

Sandwich panels TENAX are manufactured in a wide range of thickness, with different thermal insulation cores, panel joints, and profiling of the steel facings, all of which have a significant influence on the performance characteristics and the appearance of the structure. Sandwich panels TENAX with polyisocyanurate foam (PIR) core are particularly suitable for the structures with very high thermal performance and fire safety requirements, as well as for the structures with the risk of water condensation in the thermal insulation. Together with the sandwich panels TENAX the customer can also benefit from the panel design and calculation services, as well as for instructions, detailed drawings, accessories, and materials necessary for panel handling and assembly.

Minimum order 200 m2.

This is the sample price for a 40mm panel. Please send your inquiry: order@factory.sale

Step 1

Select a product.

Step 1

Select a product.

Step 2

Add to quote.

Step 2

Add to quote.

Step 3

Fill the form.

Step 3

Fill the form.

Step 4

Send a request.

Step 4

Send a request.

Step 5

Answer within 24 hours.

Step 5

Answer within 24 hours.

Sandwich panels TENAX are manufactured in a wide range of thickness, with different thermal insulation cores, panel joints, and profiling of the steel facings, all of which have a significant influence on the performance characteristics and the appearance of the structure. Sandwich panels TENAX with polyisocyanurate foam (PIR) core are particularly suitable for the structures with very high thermal performance and fire safety requirements, as well as for the structures with the risk of water condensation in the thermal insulation. Together with the sandwich panels TENAX the customer can also benefit from the panel design and calculation services, as well as for instructions, detailed drawings, accessories, and materials necessary for panel handling and assembly.

Minimum order 200 m2.

ADVANTAGES

There are no reviews yet.

No manuals available for this product.